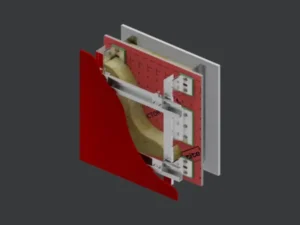

The Nvelope NV3 system is an innovative and advanced facade fixing solution that is engineered to support facade panels securely and discreetly, which is crucial for non-combustible materials like Dekton. This system helped the 111 Eagle Street project to meet the current building codes and improve the fire safety of the building.

As the construction industry continues to evolve and prioritise safety and sustainability, innovative products like Nvelope and Fischer undercut anchors are playing a crucial role in supporting the development of cutting-edge projects.

Products & Application

Featured Products: Nvelope NV3, Fischer Concealed Anchors

Project Name: 111 Eagle Street Brisbane

Head Contractor/Builder: Built

Façade Engineer: BG&E Façade

Cladding Type/Brand: Dekton by Cosentino

About Nvelope NV3

About Fischer Anchors

The DCT Fischer ACT System opens up the way for effortless and cost-efficient design of attractive, complex façades. The technology offers several times higher ultimate loads than conventional fixings. Because anchor positioning can be optimised, the bending moment within the panel is reduced by about 50% when compared to traditional systems.

This post first appeared on DCTech