Open vs Closed State Facade Cavity Fire Barriers,

What’s the Difference?

In ventilated façade systems, cavity fire barriers are essential to slowing the spread of fire through the ventilated cavity zone. At DCTech, we’re often asked about the difference between our Tenmat open state and closed state cavity barriers, and more importantly, how and where they should be used together in a façade.

Why Cavity Barriers Are Needed

Behind most ventilated façade systems is a drainage and ventilation cavity. While this gap helps manage moisture and promotes airflow, it can also act as a chimney during a fire, allowing flames and hot gases to spread rapidly. Cavity fire barriers are designed to stop this spread.

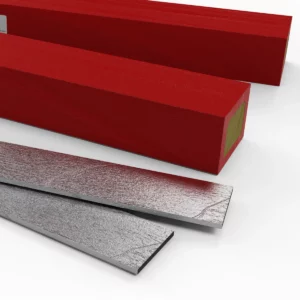

Open State Fire Barriers

What they are:

Open state (or ventilated) barriers include a non-combustible backing with an exposed front intumescent strip, creating a small ventilation gap, usually up to 20mm – 44mm.

Key Features:

- Allows drainage and vertical airflow during normal conditions.

- In a fire, the intumescent material expands to seal the cavity.

- Typically installed horizontally to maintain upward airflow while stopping vertical fire spread between floors.

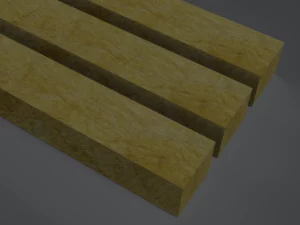

Closed State Fire Barriers

What they are:

Closed state (or non-ventilated) barriers seal the cavity from the start. They are typically made from non-combustible mineral stone wool and do not rely on activation.

Key Features:

- No ventilation or air gap.

- Permanently closes the cavity.

- Provides immediate fire resistance.

- Typically installed vertically to stop lateral (side-to-side) fire spread between compartments or façade sections.

How They Work Together

In modern façade design, both barrier types are used together:

| Installation Orientation | Typical Barrier Type | Purpose |

| Horizontal | Open state | Maintains ventilation; stops vertical fire spread. |

| Vertical | Closed state | Permanent seal; stops lateral fire spread. |

| Note: Vertical barriers do not need to be open state, ventilation is not required in this orientation. | ||

Summary

✔ Open state = ventilated, intumescent-activated, installed horizontally for vertical airflow.

✔ Closed state = permanently sealed, installed vertically to compartmentalise and stop lateral fire movement.

✔ They are not alternatives, but complementary components of a compliant façade fire protection strategy.

At DCTech, our Tenmat fire barrier solutions are tested to meet AS/NZS, and global standards, to support both architectural performance and fire safety. If you need help designing or specifying the correct fire cavity barrier layout, our technical team is here to support you.

Tenmat – Protecting Buildings, Protecting Lives