Thermal breaks

Thermal breaks are structural components strategically integrated into a building’s design to minimize heat loss and prevent thermal bridging, thereby enhancing energy efficiency and reducing heat transfer through the building envelope.

Want to Know More?

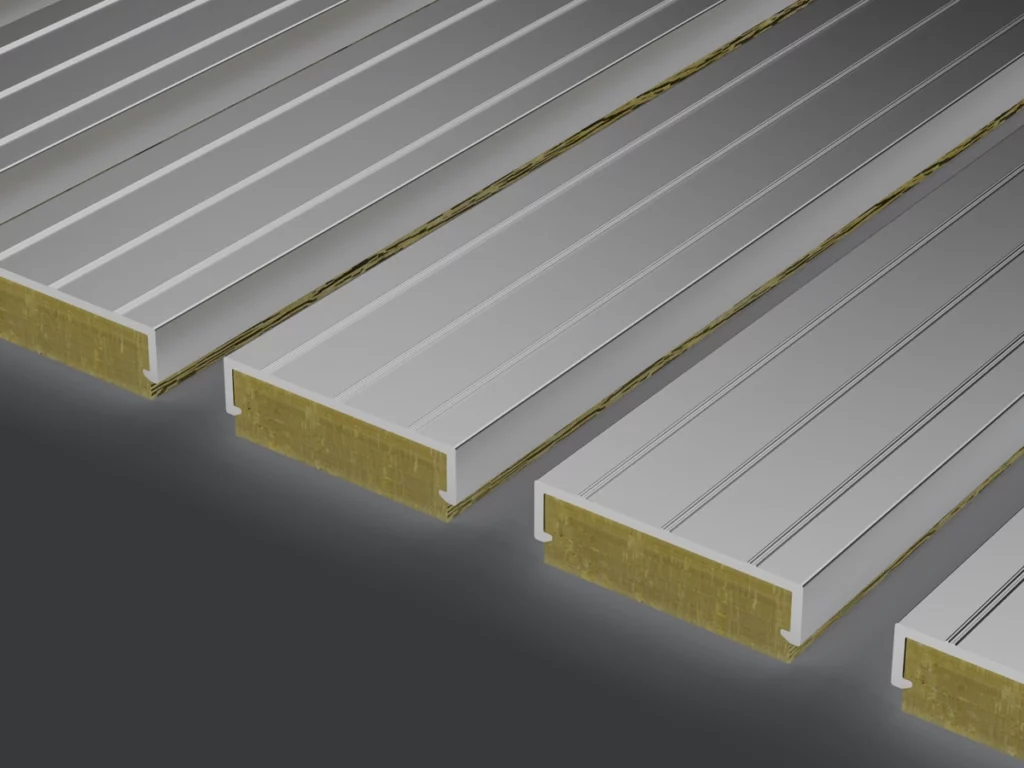

DCT VulcanWool Thermal Break Strips

Product Description

DCT VulcanWool Non-Combustible Thermal Break Strips are used to reduce the thermal bridging between external and the internal building fabric.

The increase stringency of the NCC 2019 requires that the insulation performance of walls accounts for thermal bridging through the frame. In particular this poses a significant challenge to meeting required total R-values with steel frame construction in type A, type B and protected timber construction where all insulation including a thermal break must be non-combustible.

For compliance with J0.2(c), a wall that—

(a) does not have a wall lining or has a wall lining that is fixed directly to the same metal frame; and

(b) has lightweight external cladding such as weatherboards, fibre-cement or metal sheeting fixed to a metal frame, must have a thermal break, consisting of a material with an R-Value of not less than R0.2, installed at all points of contact between the external cladding and the metal frame.

Want to Know More?

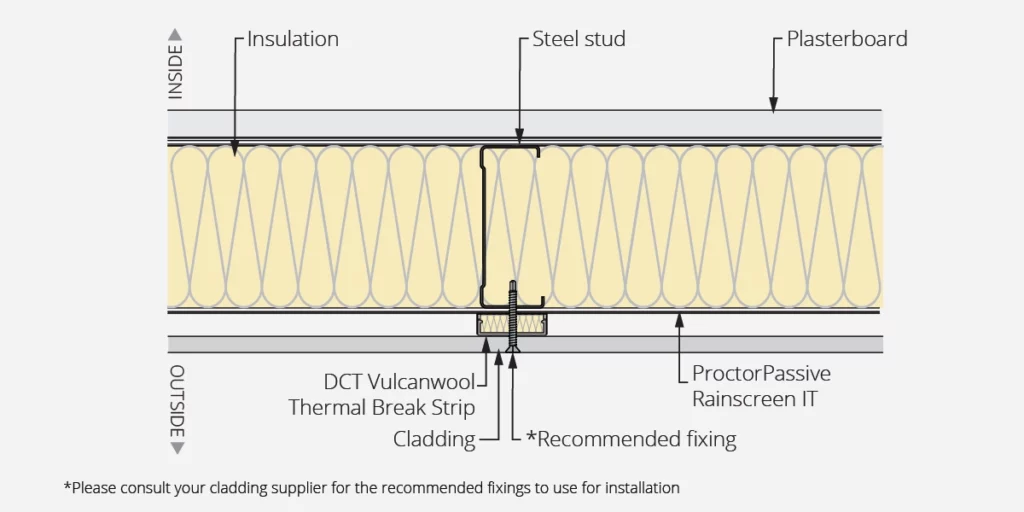

Installation

DCT VulcanWool Non-Combustible Thermal Break Strips should be installed continuously over the stud frame with the custom metal cover facing out, away from the building substrate. The thermal break strips are typically installed over a vapour permeable membrane.

Ensure proprietary fixings are not excessively torqued, resulting in the over compression of the thermal break strips. Thermal break strip compression should not exceed the nominated “thickness” dimension listed in the table below.

This product meets the requirements of Section J0.2(c) and J0.5 as a wall thermal break.