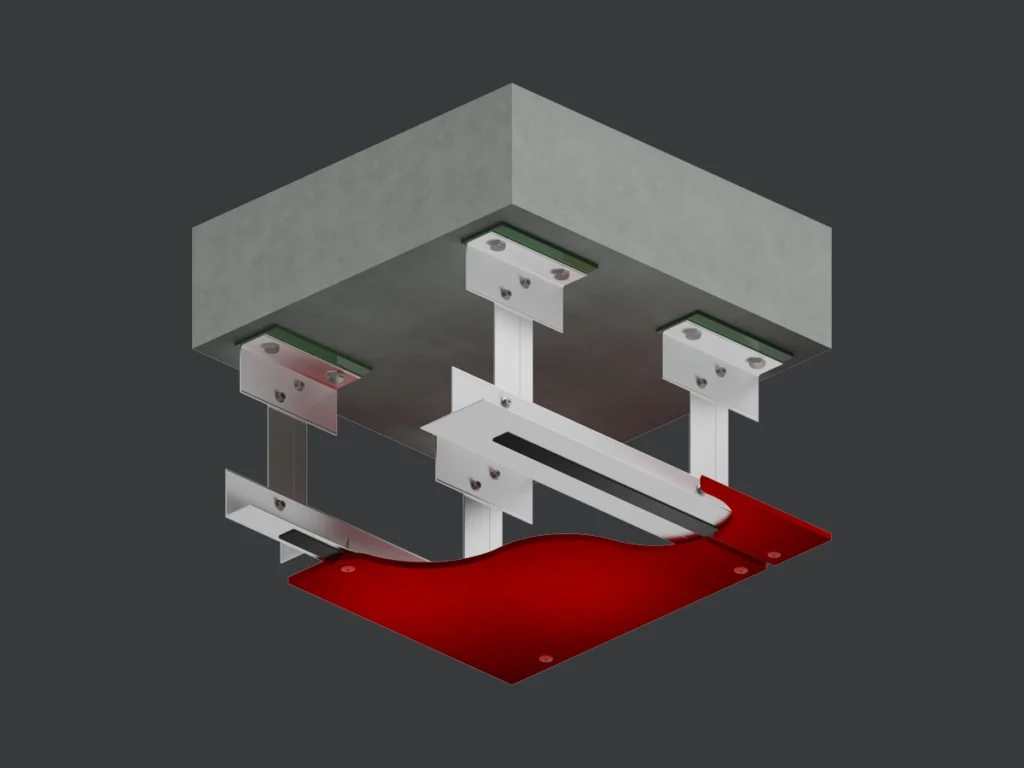

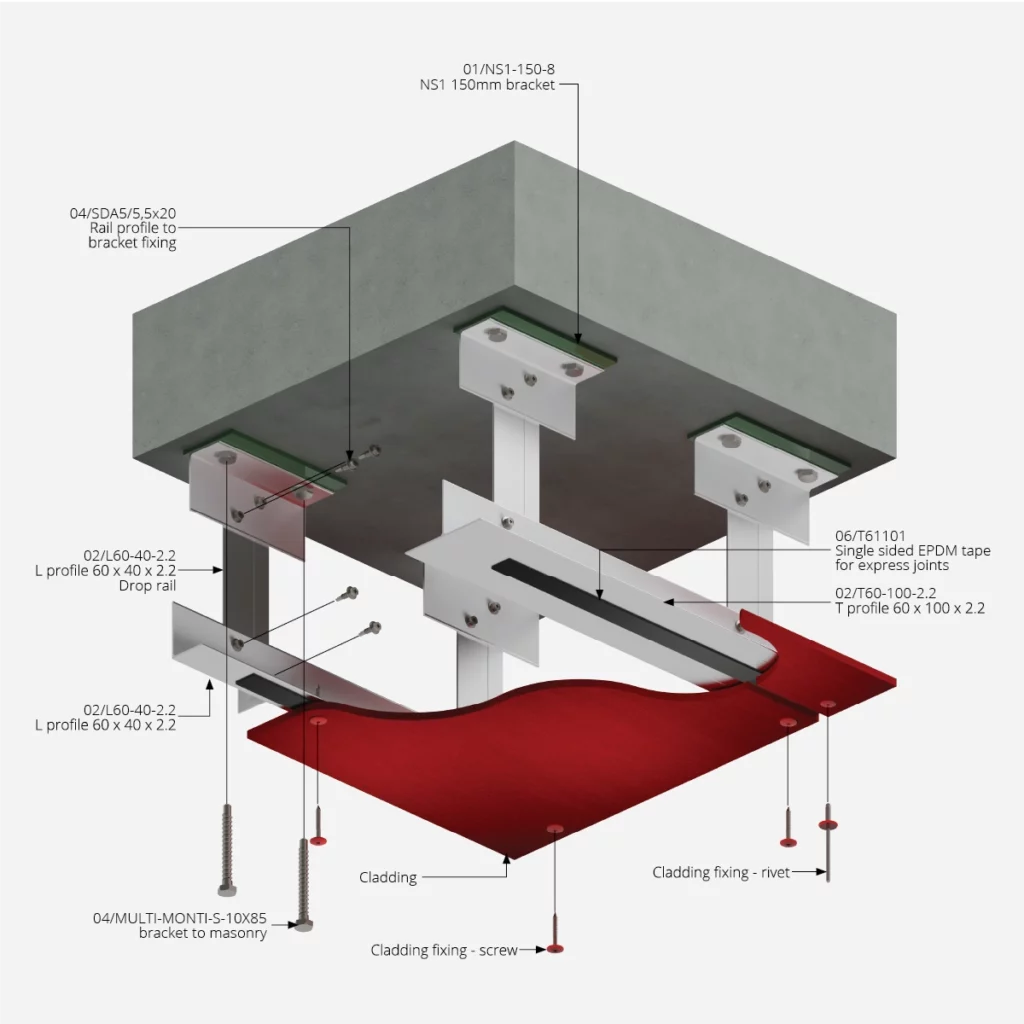

NVELOPE® NS1 System

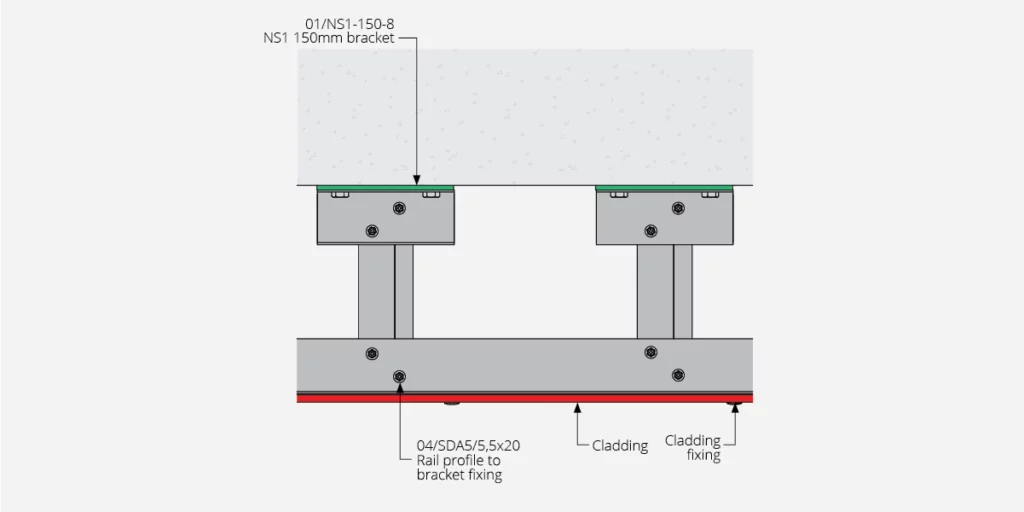

Suspended soffit system is suitable for face fixed cladding applications. NS1 can also support our NV3 rail for concealed fix soffit applications.

Want to Know More?

About

- An applicable drop zone (distance from floor slab to back of panel) for this application is between 120mm – 1000mm. The soffit application can be fixed to steel frame, timber frame or concrete substrates.

- Depending on the drop-down zone, wind load and panel weight some soffits will need a brace bar intermittently within the cladding support system. This brace-bar can be cut out of L rail. (Please seek advice from our technical team).

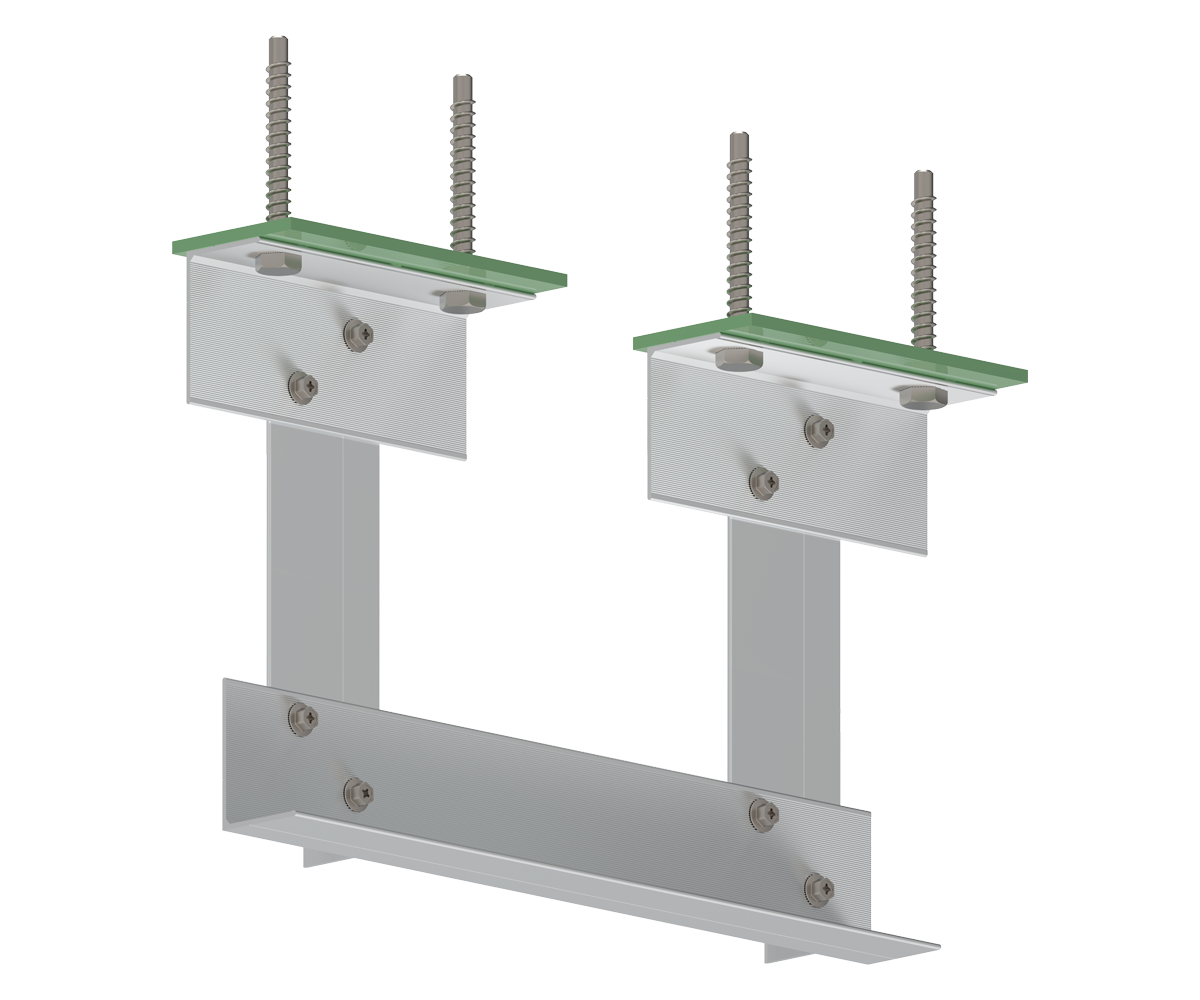

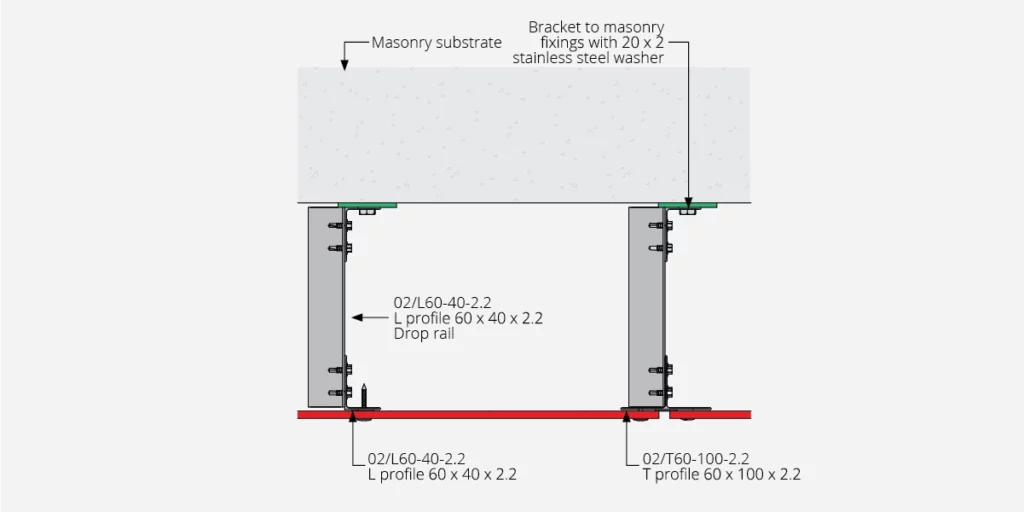

- The System is prominently composed of NVELOPE's L60-40-2.2 Rail, this is available in 6-meter lengths. Options available for cutting to bespoke sizes depending on the soffit zone and design. The length of the down standing L rail absorbs the expansion and contraction of the soffit panel.

Applications

NVELOPE NS1 Soffit system is suitable for face fixed applications, with a maximum panel weight of 75kg/m2.

Often soffits are not insulated but if thermal bridging is an issue, flat plastic isolators can be supplied to stop thermal bridging and bimetallic corrosion.

NVELOPE T rails are fixed to the bottom of the down standing L rails where panel joints occur; available in 100mm, 120mm face widths. L rail support for intermediate and end positions.

DCT Nvelope hold extensive stock of the L60-40-2.2 and T rails that can be cut in house resulting in quick delivery to site. This system can be used to create sloping soffits by special cutting to suit the angle.

- Fibre cement Panels

- Glass reinforced concrete (GRC)

- High pressure laminate (HPL)

- ACM & Solid Aluminium Cladding

- Metal rainscreen panels

- Brick Slips

- Terracotta

- NV3 concealed system

NS1 can also be used as the base system for NV3 concealed soffit fixing of cladding panels.

Features

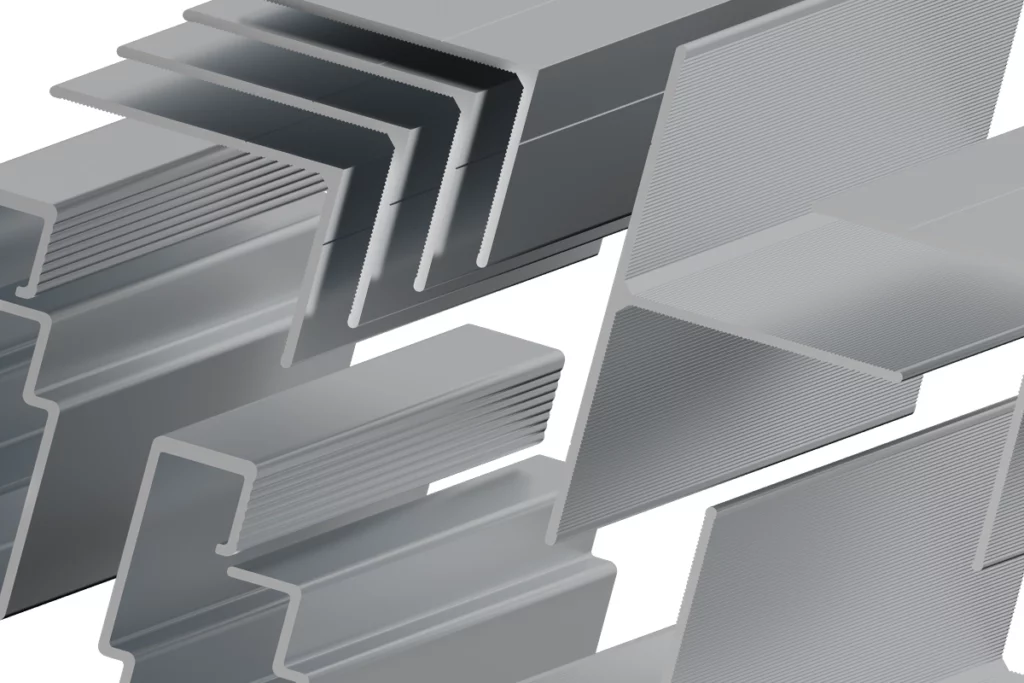

- Manufactured from extruded aluminium alloys conforming to AS/NZS 1866:1997 (material) and EN 755 production standards.

- Non-Combustible to AS1530.1

- Suitable in high corrosive environments C4 and C5.

- Thermally broken to meet Section J NCC 2019 & 2022 thermal bridging requirements.

- Engineered to Australian Standards.

Documentation

Need more system info? Download our detailed system drawings, installation guides and associated data sheets.

Download NS1 DocumentationOrder AutoCAD DrawingsMaterial

The selection of materials to use in the construction of a subframe system within a rainscreen façade is of paramount importance. Material choice can also affect the thermal performance of the overall rainscreen in addition to engineering assurance.

- Aluminium is inherently corrosion resistant however this can be complemented and further improved by additional treatment including anodising and powder coating.

- All NVELOPE systems only use the superior 6005 T5 alloy, which provides superior strength and performance over and above other commonly used aluminium.

Standards

- AS/NZS 1170.0 Structural design actions Part 0: General principles

- AS/NZS 1664.1 Aluminium structures Part 1: Limit state design

- AS/NZS 1866 Aluminium and aluminium alloys – Extruded rod, bar, solid and hollow shapes

- AS1530.1 Methods for fire tests on building materials, components, and structures Combustibility test for materials