NVELOPE® NV1 System

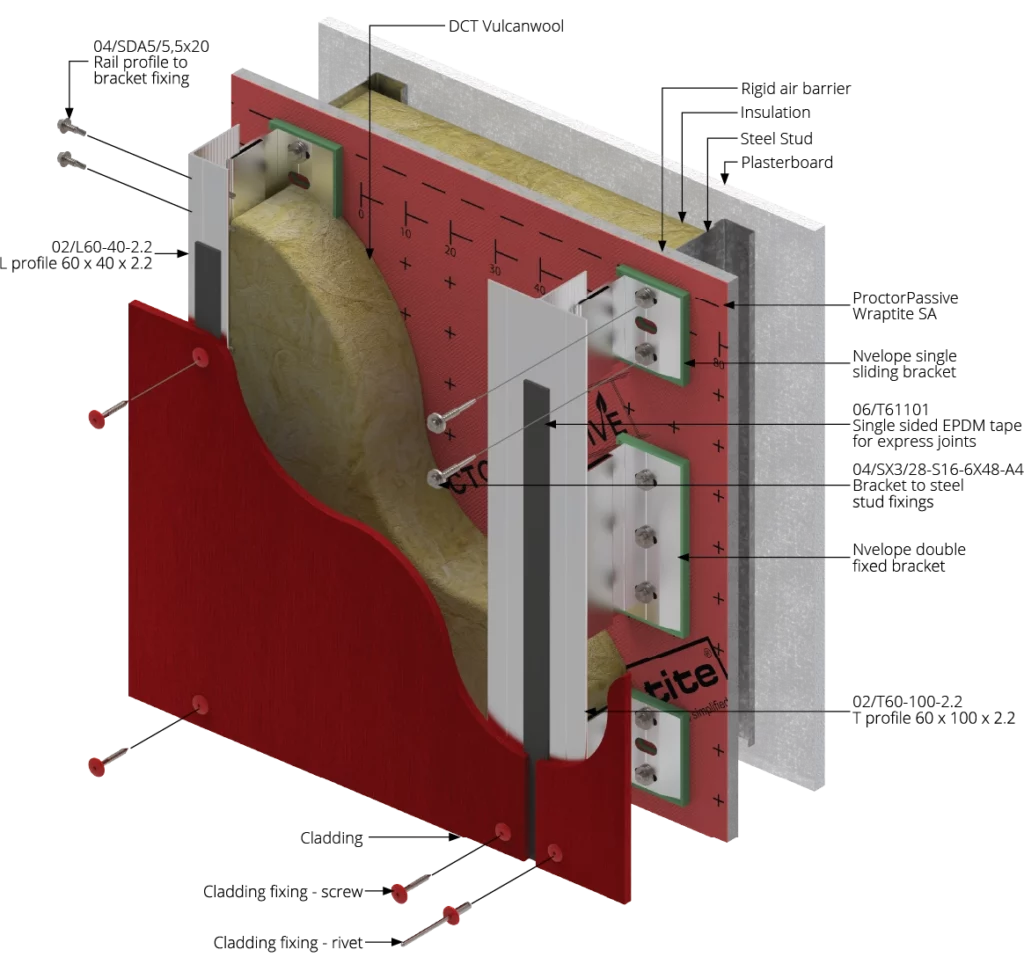

Suitable for face fixing / rivet fixing cladding elements to e.g. fibre cement, high-pressure laminate (HPL), ACM and metal rainscreen panels. NV1 is the basis of all NVELOPE vertical support systems.

Want to Know More?

About

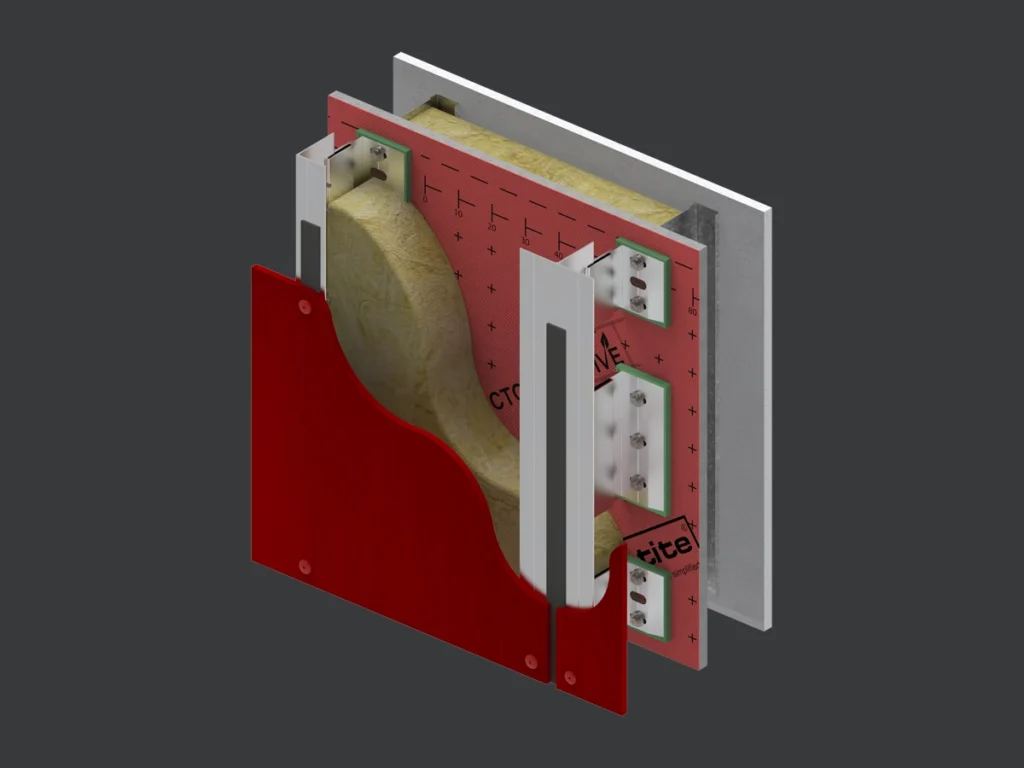

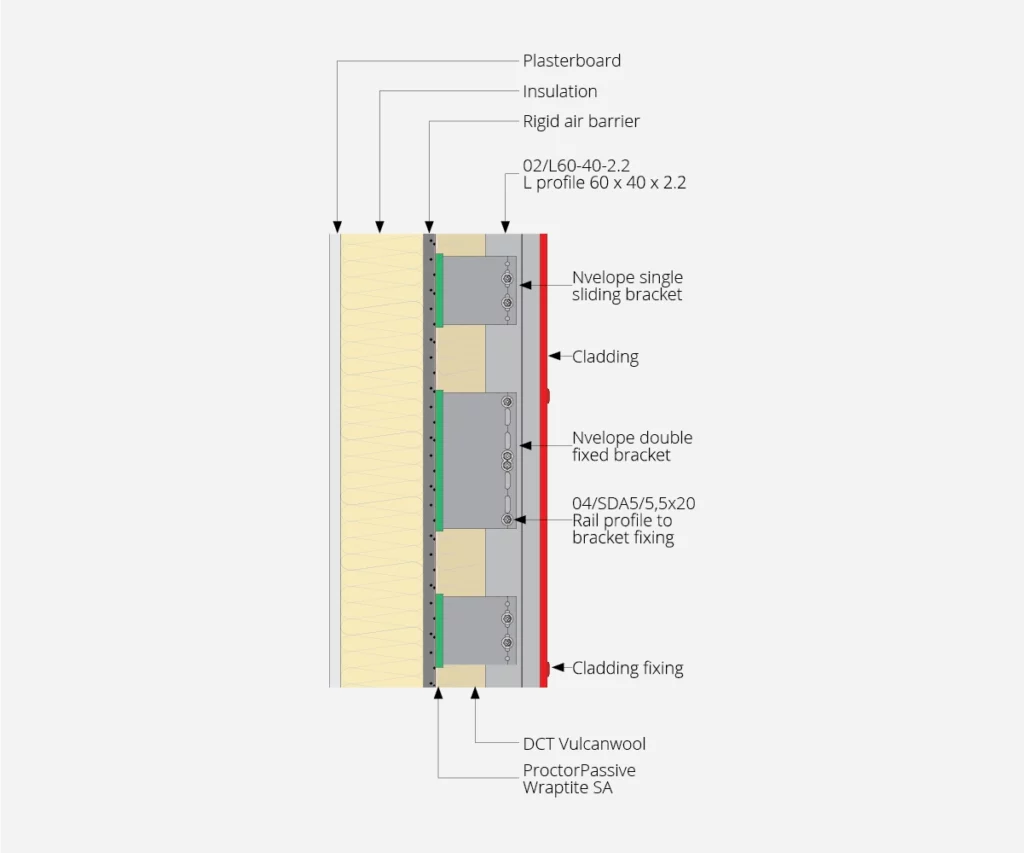

- NV1 is the NVELOPE subframe system for vertical cladding applications.

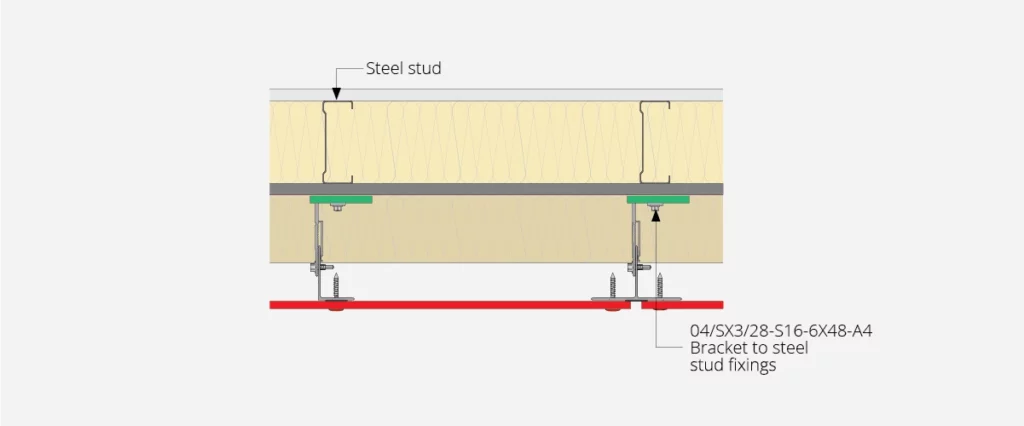

- NVELOPE 'T' and 'L' profiles are fixed using NVELOPE support brackets, fixed through a series of fixed and sliding points.

- NVELOPE flexible point brackets absorb wind loading and allow for expansion and contraction.

- NVELOPE fixed point brackets absorb the vertical dead loads.

- NVELOPE bracket spacing is determined by cladding options such as the dimensions and weight of the façade cladding, local wind loads and cladding zone.

Applications

Adjustable, thermally broken, sub-framing system – NV1 is used for face fixing, rivet fixing, and screw fixing of cladding elements. For example:

- Fibre cement Panels

- Glass reinforced concrete (GRC)

- High pressure laminate (HPL)

- ACM & Solid Aluminium Cladding

- Metal rainscreen panels

- Brick Slips

- Terracotta

NV1 is the basis of all vertical NVELOPE support systems.

Features

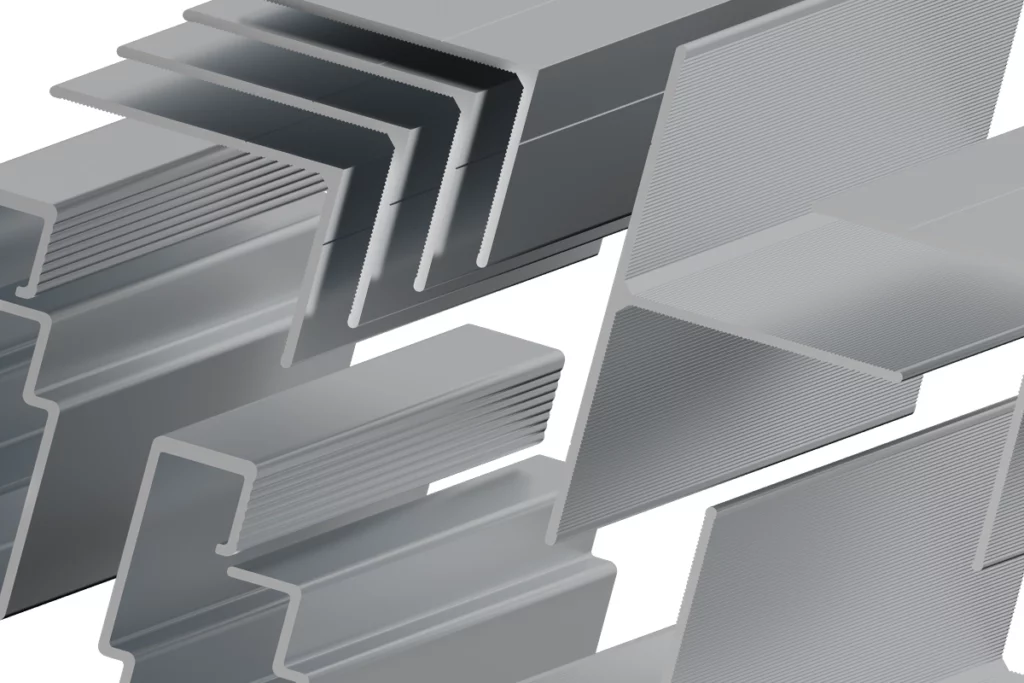

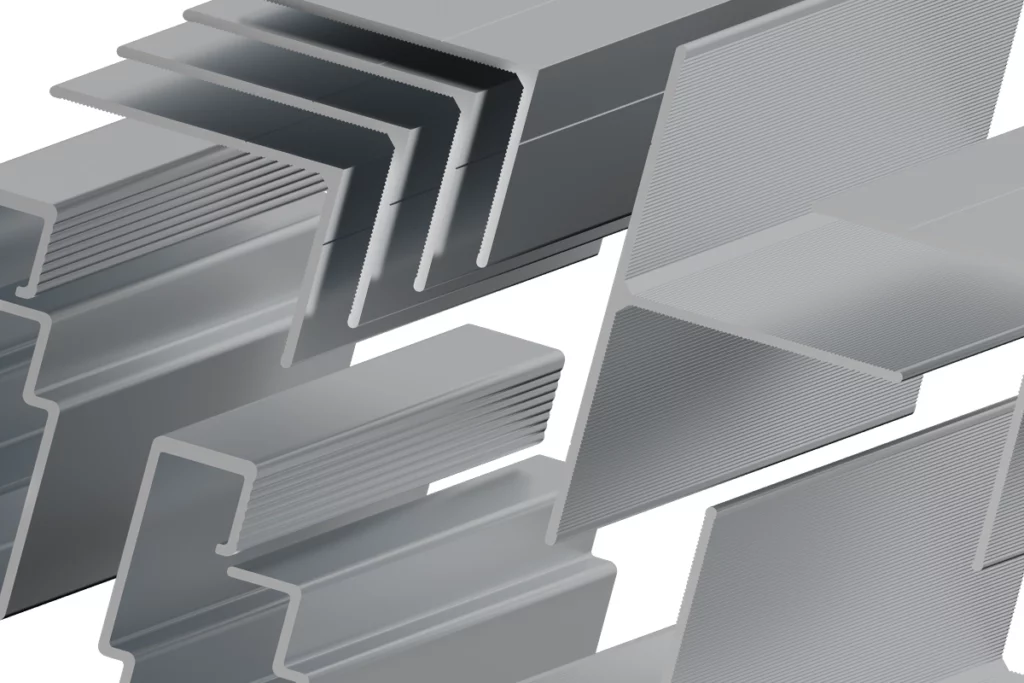

- Manufactured from extruded aluminium alloys conforming to AS/NZS 1866:1997 (material) and EN 755 production standards.

- Non-Combustible to AS1530.1

- Suitable in high corrosive environments C4 and C5.

- Thermally broken to meet Section J NCC 2019 & 2022 thermal bridging requirements.

- Engineered to Australian Standards.

Documentation

Need more system info? Download our detailed system drawings, installation guides and associated data sheets.

Download NV1 DocumentationOrder AutoCAD DrawingsMaterial

The selection of materials to use in the construction of a subframe system within a rainscreen façade is of paramount importance. Material choice can also affect the thermal performance of the overall rainscreen in addition to engineering assurance.

- Aluminium is inherently corrosion resistant however this can be complemented and further improved by additional treatment including anodising and powder coating.

- All NVELOPE systems only use the superior 6005 T5 alloy, which provides superior strength and performance over and above other commonly used aluminium.

NV1 is the basis of all vertical NVELOPE support systems.

Standards

- AS/NZS 1170.0 Structural design actions Part 0: General principles

- AS/NZS 1664.1 Aluminium structures Part 1: Limit state design

- AS/NZS 1866 Aluminium and aluminium alloys – Extruded rod, bar, solid and hollow shapes

- AS1530.1 Methods for fire tests on building materials, components, and structures Combustibility test for materials

Material

The selection of materials to use in the construction of a subframe system within a rainscreen façade is of paramount importance. Material choice can also affect the thermal performance of the overall rainscreen in addition to engineering assurance.

- Aluminium is inherently corrosion resistant however this can be complemented and further improved by additional treatment including anodising and powder coating.

- All NVELOPE systems only use the superior 6005 T5 alloy, which provides superior strength and performance over and above other commonly used aluminium.